Introduction: Enhancing Manufacturing with Complete Production Cells

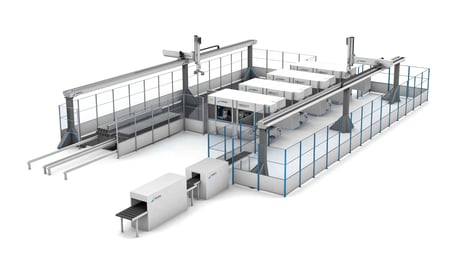

In the evolving manufacturing landscape, every manufacturer competes to achieve greater flexibility, higher quality, and increased productivity. Integrating complete production cells for workpiece handling marks a significant leap forward and is one way to enhance productivity and remain competitive. This blog post introduces Modig's complete production cell for workpiece handling. A solution from one single source that brings together:

- Infeed conveyor lines for aluminum extrusions

- HHV3 machining centers

- GRX80-S top entry gantry robots

Infeed Conveyor Line for Aluminum Extrusions

The infeed conveyor line is the entry point for aluminum extrusions into the production cell. This system is designed to handle materials efficiently and prepare them for machining.

HHV3 Machining Centers

At the heart of the production cell lies the HHV3, a universal machining center available in configurations that support both four and five-axis machining. With the option of one or two spindles, the HHV3 excels in high-volume production, processing uncut bars and extrusions of unlimited length. Its capability to produce numerous parts from a single block of material, all in one setup without the need for work holding, stands out as a significant advantage.

GRX80-S Top Entry Gantry Robots

The GRX80-S top entry gantry robots are pivotal in material infeed and part outfeed handling within the production cell. Their customized End Of Arm Tooling (EOAT) allows for precise and efficient handling of parts, significantly enhancing the automation system's flexibility and efficiency. The robots' ability to move at speeds up to 8.2 feet per second (2.5 m/sec) ensures swift and smooth operations.

Flexible Machining and Automation Solutions

Modig's production cell offers unparalleled flexibility for manufacturing a wide range of high-quality parts. Integrating machining and automation solutions from a single source ensures stable cycle times and excellent repetition accuracy. Such a setup enhances the production quality and provides a safe and easily accessible environment for operators, allowing for a compelling overview of all activities through a user-friendly HMI panel.

Production Cell Layout and Safety

The design of the production cell emphasizes safety and ease of access during the milling process. Operators can monitor the entire production cell, ensuring optimal performance and addressing any issues promptly, resulting in a conducive work environment that prioritizes the workforce's well-being.

Integration and Acceptance Testing

One of the critical benefits of sourcing the complete production cell from a single provider is the opportunity to simultaneously conduct acceptance testing for the machining solution and the automation system. This integration ensures that all components work seamlessly together, giving customers confidence in the system's reliability and efficiency.

High-Quality Components and Control System Platform

The foundation of both the machining center and the automation system is built on high-quality components and a unified control system platform. This consistency ensures that the entire production cell operates harmoniously, maximizing the robots' movements' efficiency and the machining processes' precision.

Benefits of Using Top Entry Gantry Robots

Utilizing top entry gantry robots brings several advantages to the production cell. Their design minimizes the need for expensive floor space and reduces labor requirements, contributing to cost savings and a shorter return on investment compared to manually operated solutions.

The MODIG Concept: Machining and Automation Solutions

To understand the full potential of this integrated production cell, one must look at the MODIG concept, which embodies the fusion of machining and automation solutions. By embracing this concept, manufacturers can significantly enhance their productivity through automation, setting a new standard in manufacturing efficiency.

In conclusion, the complete production cell for workpiece handling from a single source represents a pivotal advancement in manufacturing technology. By integrating efficient infeed systems, advanced machining centers, and dynamic gantry robots, this solution offers a flexible, high-quality, and cost-effective approach to production. As we continue to explore the benefits and applications of such integrated solutions, it becomes clear that the future of manufacturing lies in the seamless convergence of machining and automation technologies.

Discover how you can maximize your productivity with automation and learn more about the MODIG concept in the article Meet Modig, A supplier of Both Machining and Automation Solutions. Schedule a meeting with our team to learn how our complete production cells can strengthen your business case.

.jpg)