An automation system optimized to work seamlessly with your high-performance machining solution is pure gold for your productivity. By choosing automation- and machining solutions from one source, you take your production to the next level and gain many synergies.

In today's fast-paced manufacturing of parts for essential industries, including aerospace and automotive, all actions that push your production ahead of your competitors give the same feeling as standing on the podium in the Olympic games. Investing in efficient and reliable automation equipment is one way to gain competitive advantages. With carefully selected strategies and solutions for workpiece handling, you can unlock the maximum productivity of your machining center.

Added values with automation

With automation for machining centers, it is no secret that you will increase your output, reduce cost, and improve quality. With robot handling, the loading and unloading process will be more efficient, reduce the time the machine is idle during loading and unloading, and pave the way for higher output. Achieving a more stable cycle time and better repetition accuracy in handling results in higher quality and less damage to the manufactured part. On the bottom line, the cost will be reduced due to reliable automation solutions

Machining solutions and automation solutions from one source

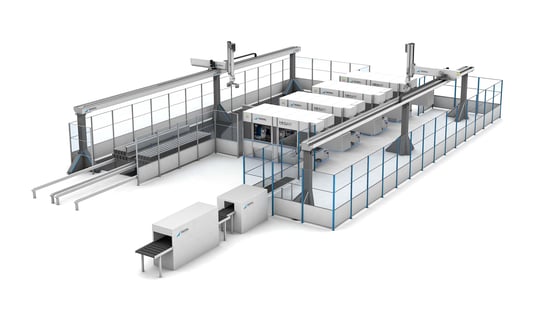

To secure the highest possible productivity, your automation system and machining solution must function seamlessly together 24/7 without sacrificing safety and meeting demanding floor space requirements.

In the worst-case scenario, the machine does not work impeccably with the automation system. Conflicts between the different systems lead to undesirable downtime. In other cases, the workflows could be more efficient to get the desired result. These examples show how easily productivity gains from the quickest and most precise machine are undermined if the automation solution is not optimized with the machine solution and the customer's needs. Is it possible to prevent this problem?

One way to ensure that the machine and the automation solution are compatible and will work like a dream together is to choose a machining center and automation from a single source.

The advantages of choosing a single source for machining and automation solutions

One of the advantages of utilizing a single source solution for high-performance machining and automation solutions is simplified integration because the provider deeply understands the different components and how they work together, allowing for a unified integration process. By cooperating with a single provider, customers can ensure that all components and systems work seamlessly without compatibility issues, reducing the risk of downtime and errors and improving overall productivity and efficiency.

Another advantage of a single-source solution is streamlined support and maintenance. When working with a single provider, customers have a single point of contact for all their support and maintenance needs. This can help reduce downtime and increase overall equipment uptime, as any issues can be quickly identified and resolved.

Meet Modig, a machining and automation solutions supplier, and discover more about the advantages of choosing a single-source provider.

Contact us now for additional information!