Our investigation into the evolution of extrusion machining continues. In part one, we delved into its origins and the emergence of CNC machines. In part two, we will explore high-speed machining and the introduction of the world's first machining center with rotary tables and guide you toward available solutions today.

High-speed machining

After many trials and errors, Modig Machine Tool and SKF (AB Svenska Kullagerfabriken, a Swedish bearing and seal manufacturing company) devise a solution of larger ball bearing with ceramic balls instead of steel balls. This solution was less sensitive to friction. In collaboration with KTH (Kungliga Tekniska Högskolan/Royal Institute of Technology in Stockholm - one of Europe's leading technical and engineering universities), the technicians at Modig figured out how the machine should best be constructed to deal with the forces and deliver remarkable precision even at high speed. As a result, one of Modig's endeavors involved improving the stability of rail guides used to control raw material feeder units. To achieve this, they used hardened steel to construct the rails, significantly reducing vibration when in contact with the material being processed.

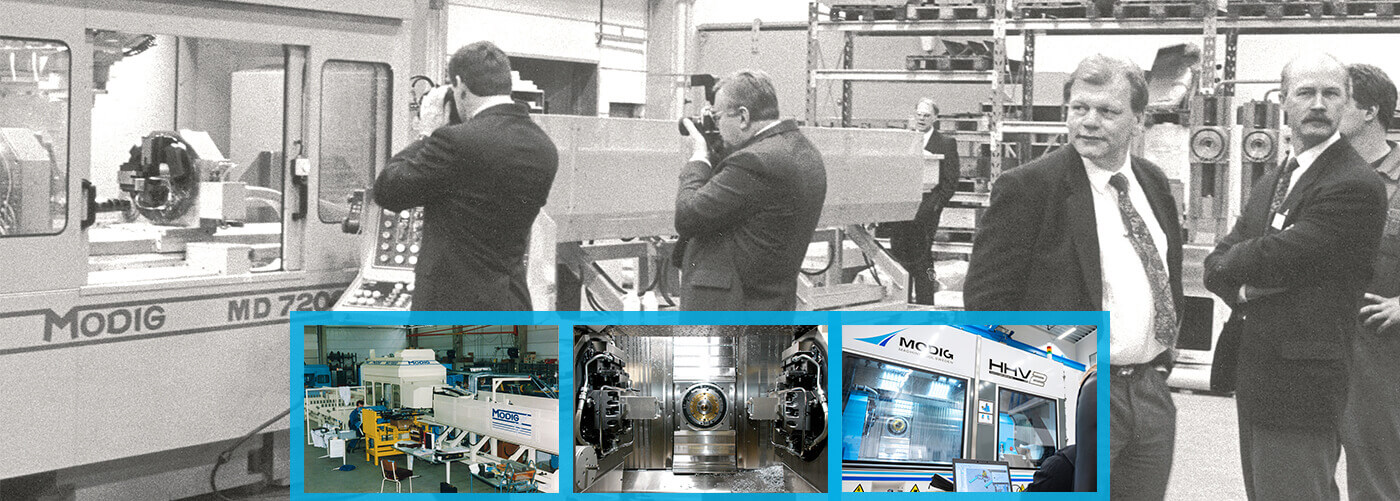

Additionally, ball bearings were placed side by side to neutralize the amplification of vibrations, and a film of oil was introduced to absorb a portion of the vibrations. This mechanical function was integrated with the computer control system, which allowed headstocks to operate at a maximum rev count of 20,000 rpm. The machine MD 7000 was born, and Modig got better recognition worldwide with this machine.

The Worlds first extrusion machining center with rotary tables

Despite the machine's high precision operating at 20,000 rpm, selling it was difficult as customers hesitated and preferred to wait until the product matured. However, a Swedish aircraft producer needed a flexible machine to process aluminum profiles of different sizes at high speed without compromising quality.

.jpg?width=558&height=348&name=MODIG-extrusion%20machining-Profile%20Line%20(1).jpg)

In the early 1990s, the machine that exceeded the customer's specification was ready. The machined was named Profile Line and was a further development of the MD 7000. The Profile Line was a highly efficient machine that could perform precise routing and drilling tasks at incredible speeds. It had automatic entry and exit functions and could handle several-meter-long aluminum profiles. It was very flexible, with the ability to produce approximately 1,700 unique types of details. The machine could create details as small as 20 millimeters (0.86") and as large as six meters (236") using the same profile piece, making it an incredibly versatile tool.

What Modig has accomplished raised many questions: How fast could you machine different materials? Could Dr. Salomon's untested theories from the 1920s be correct in suggesting that heat generation decreases after a specific processing rate is reached?

The result from the customers' factory's one-year test period could be summarized in one word, WOW! Through their research, it was proven that high-speed machining offers numerous benefits. These include significant time savings and reduced heat generation despite the increased cutting speed, which validated Dr. Salomon's hypothesis. As the cutting speed increased, most heat was dissipated with the metal shavings, reducing tension in the material. This extended the lifespan of both tools and machinery. However, it was also found that top speeds were not suitable for all materials. Optimum processing of different materials required varying headstock types, numbers of revs, and tools.

Discover our extrusion machining solutions. Download our product sheets

Extrusion machining solutions today

Extrusion machining has come a long way since its inception, and Modig Machine Tool has been at the forefront of this evolution. Today the company provides turnkey solutions, with single, twin-spindle, or four spindles, HHV and Mill-Ex, that could be combined with optional automation solutions, from single in-feeders and out-feeder solutions to complete production cells.