It has been over thirty years since Modig Machine Tool introduced the world's first extrusion machining center with a rotary table. The company has since pushed the boundaries of what is possible in extrusion machining, evolving its machines to enhance the user experience. Discover the remarkable journey Modig has made to build expertise in extrusion machining and explore their machines' evolution. In this part, we explain how it all began.

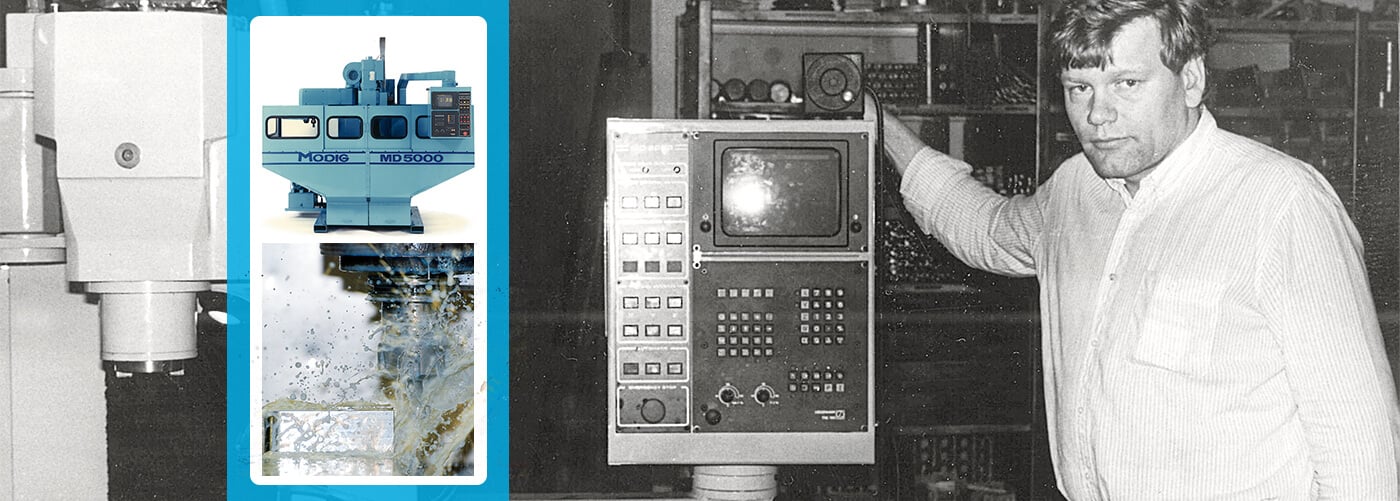

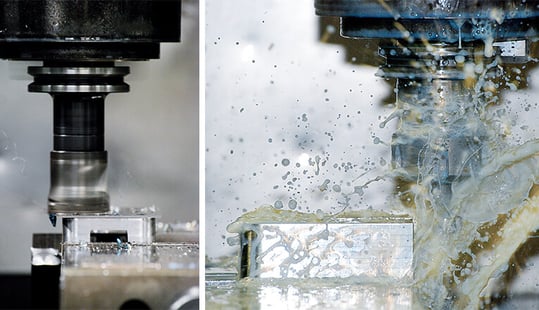

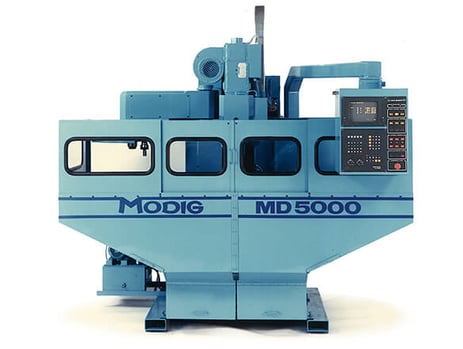

We travel through time and end up long before extrusion machining solutions spelled HHV become the preferred option in many metal workshops. Instead, manual drilling and routing machines were utilized to turn extrusions into finished parts. However, introducing computer numerical control (CNC) technology was a game-changer for extrusion machining. MODIG was not late to jump on the train of computerization and introduced its first model of computer-controlled machines. MD5000 was a complete multi-tasking machine made for routing and drilling, capable of processing at different speeds in all directions and equipped with an automated tool-changing system. Taking the giant step from manual machines to embracing CNC technology was a necessary evil to stay competitive as a machining manufacturer.

The rise of CNC machines

The rise of CNC machines led to a shift in customer demands for faster machines capable of performing more processes. To keep up with the competition and meet the customers' needs, all machine manufacturers started to produce more rigid and robust machines capable of handling higher speeds. However, what every machine manufacturer dreamt of in the late 80s was how they could be able to showcase the spindle with the absolute highest speed rate. From machines able to perform 5,000 rpm, the manufacturers were chasing speeds of 15,000 – 20,000 rpm. These speeds were still a dream when Modig Machine Tool contacted SKF (AB Svenska Kullagerfabriken, a Swedish bearing and seal manufacturing company) and started a collaboration to develop a solution to perform high-speed machining above 15,000 rpm. Something nobody in the world has been able to accomplish with maintained precision levels.

Innovation and technical ingenuity

With the implementation of CNC technology, Modig left the off-the-shelf devices behind and shifted focus towards more innovation to be better prepared to meet the competition and fulfill the customer's needs. It takes immense courage to achieve a business transformation as Modig did. Perhaps it's not coincidental that "Modig" means "brave" in Swedish. In the old good days, all new Modig machines were based on a previous model, but now a new machining solution was developed from scratch. At this time, the team at the Modig factory in Virserum had gained ample experience and technological expertise, enabling them to be more innovative and push boundaries. But would their technical ingenuity be enough to achieve the unprecedented feat of developing a machine that can operate at speed over 15,000 rpm (something we all know is possible today), all while maintaining optimal quality?

To be continued! Read The Evolution of Extrusion Machining Part 2 and take part in the story from the first solution to modern technology.