By upgrading your machinery with new machining centers, you can achieve the desired speed and precision, significantly improving the quality of your work and transforming your business. However, with so many options available, it can be challenging and take time to select the right machining center. How do you choose the right one? In this blog post, we will guide you in choosing between the main types of machining centers.

In a far-flung corner of the world, there is a factory where skilled workers tirelessly produce metal parts for the automotive industry. Unfortunately, the company has recently faced tough competition and is in desperate need of help to reduce costs per part. This has resulted in demotivation among the hardworking employees. However, there's hope! The Management has a significant decision. They must decide whether to invest in cutting-edge machines to boost productivity or streamline operations by reducing the workforce. With so much at stake, the company needs to make bold decisions to maintain its position as a leading manufacturer. It's time for a thrilling transformation that will propel the company to new heights of success.

Unfortunately, buying machines is not like going to the sports store and simply buying the same pair of shoes the winner had in the New York Marathon. And if they do not work, return them and buy new ones. The part company who need to purchase new machines must carefully analyze and evaluate the various choices to choose the right machining center. Then, decide and wait until the machine is ready for delivery according to the desired specification. Test runs are then processed to see if the new machining solution delivers what the machine tool builder promises. This process can take months.

If you have ever walked through hall after hall filled with processing machines at the IMTS fair, you realize that the choice is not easy because the range is enormous, and each manufacturer promises more. Within a budget, the company has to find a machine that offers high productivity with high quality based on the parts' shape and complexity, the materials used, and the machine's size.

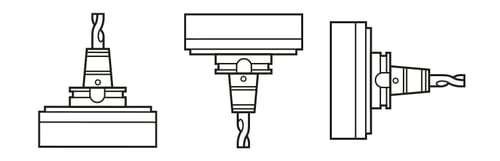

To make it easier, we will focus on the primary division of different machining models according to the spindle's orientation when processing: inverted, vertical, or horizontal. These are all advanced multi-axis machine tools with high spindle speeds and distinctive features and benefits that make them ideal for various applications. We will examine the differences between inverted, vertical, and horizontal machining centers and explain when it is best to use the different options.

Inverted machining centers

An inverted machining center is a new machine equipped with one or more spindles machined from below. It is best suited for machining small and large complex components in soft and hard metal, where chip removal is essential since working from below allows for better chip evacuation. Hard metals are typically more challenging to machine, but inverted machining centers do it effectively as it eliminates the recutting of chips damaging the tools.

The machines on the market are stable "standard machines" perfect for many industries such as aerospace, automotive, semiconductor, and heavy equipment, where precision and speed are crucial. These machines provide greater accuracy, shorter production times, and better chip handling.

Vertical machining centers

The significant difference between vertical machining centers and the other two machine types is that the spindle machining of the workpiece takes place from above. A spindle machining parallel to gravity is always superior in stability and rigidity, enabling accurate machining at high speed. This type of machine is very efficient and is considered the first choice for larger parts that are not so complex.

Horizontal machining centers

The spindle is parallel to the production floor in horizontal machining, allowing it to approach the workpiece from the side. This machine type suits a wide range of workpieces that require machining on multiple sides and provides speed, rigidity, and accuracy with a shorter set-up time.

Choosing spindle orientation for your next machining center

Choosing the right machine type can be a challenging task. It depends on your production needs and goals, the specific requirements of your project, and the work you need to do. There are several factors to consider, such as your budget, materials, capacity, and the size of the parts you will be machining. The process of decision-making is similar to selecting new players for the next season in the British professional soccer league, the Premier League. Making the wrong decision can cost you several competitive advantages over your rivals and result in lost matches, which, in turn, can translate into business terms as lost customers, reduced revenue, and, ultimately, downsizing. Therefore, it is crucial to make an informed decision when choosing the right machine type for your project. All types have their shortcomings and advantages. Therefore, evaluating all factors to make you a competitive producer is crucial when you purchase a machine.

The cost per part is the key

Are you ready to take your manufacturing process to the next level? The cost per part is the key when selecting the perfect machining center for your business. By calculating the cost per part, you can identify the most cost-effective option to help you save money and produce high-quality products that meet your customers' demands. Get ready to transform your business and revolutionize your production process!

Schedule a meeting to find your next solution