Extrusions shape the world. The impact of extrusions on our world cannot be denied, as they shape the structures and objects around us. From my office in Kalmar, Sweden, I observe a busy parking lot filled with hundreds of cars, towering office buildings, and a plane gliding through the clear blue sky on its way to Copenhagen from Stockholm - all constructed using extrusion components. If you want to learn more about extrusion machining, keep reading this blog.

How an extrusion is made

Extrusion is a metal-forming manufacturing process to create objects with specific cross-sectional profiles.This process is commonly used in producing metal parts, such as aluminum profiles. The manufacturing and production process begins with the design phase, where the extrusion is shaped, and features are incorporated to facilitate connection, minimize finishing work, and simplify assembly.

The next step in the process is when a material is heated to a specific temperature and pushed through a die using a hydraulic press. The final product is a long, continuous shape that can be cut to any length desired. There are infinity variations of extrusions to be used to reduce the necessity for additional work and enhance the effectiveness of fitting and assembly. What is your extrusion shape?

.jpg?width=487&height=254&name=Extrusion%20differentations%20(2).jpg)

Extrusion Machining

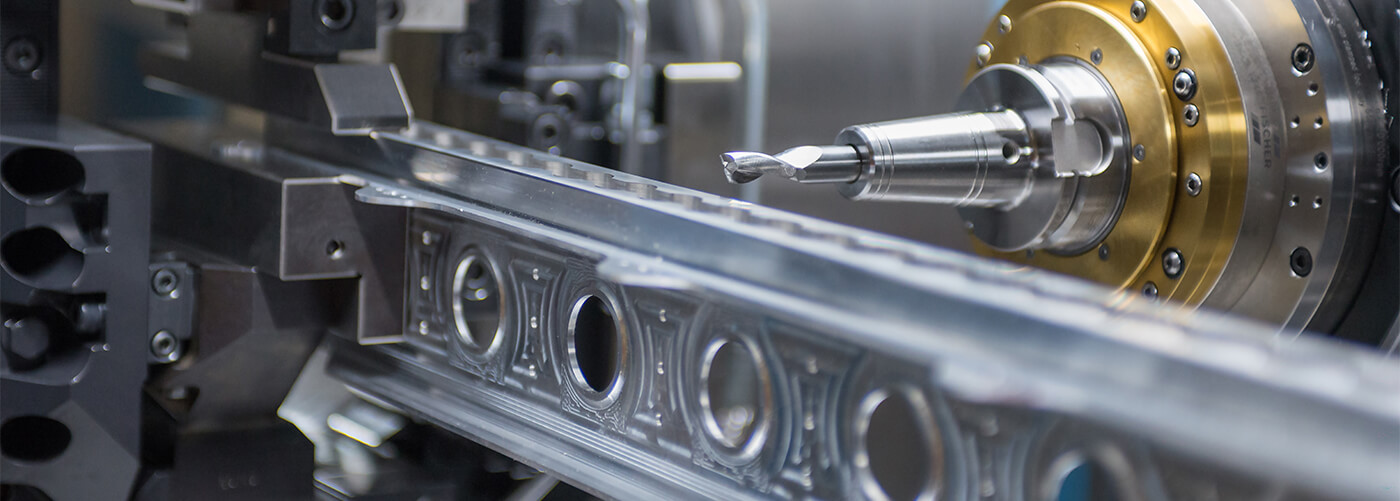

A CNC machining center performs various techniques to achieve the desired shape with pockets, holes, and other features, including sawing, deburring, drilling, turning, milling, and tapping. The CNC machining center is responsible for perfectly cutting and shaping the extrusion. Watch our videos to understand extrusion machining better.

Example of parts made of extrusion machining

Extrusion machining is a cost-effective and efficient solution many industries have widely adopted, partly due to its high strength-to-weight ratio. The aerospace industry has used this technology for years in for example seat tracks and wing stringers. In the automotive industry, it is used for electric vehicle components such as cross members for battery trays. Many industries benefit from using extrusions, and if you look around, you will see many door and window extrusions since extrusions are a staple in the construction industry.

Seat track, aerospace

A seat track is affixed to the aircraft floor, attaching passenger seats instead of directly to the base. This method allows seats to be securely fastened while enabling them to be easily moved or removed by simply detaching them from the seat tracks.

This component is produced within 32 minutes in the HHV horizontal machining Center from Modig. The previous known time with a known multi-machining center is 70 minutes. See all our case studies.

Cross member, automotive

The cross member is a crucial part of an electric vehicle's battery structure, typically constructed in steel or aluminum extrusion. The cross members are placed within the battery enclosure and hold the individual batteries.

A MODIG HHV produces a cross member within 6 min and 46 sec, compared to 27 minutes before. Learn more about Modigs extrusion machining solutions for electric vehicles.

Extrusion: Cost-effective and efficient

To sum up, the extrusion process has proved to be an extremely cost-effective and efficient method of producing top-notch parts that meet the requirements of contemporary manufacturing. It is a versatile technique capable of creating various shapes and sizes, which makes it a preferred option for numerous industries. In general, the extrusion process is a reliable and efficient manufacturing method that continues to play a crucial role in shaping the future of production.